Choosing the right electrical cables is crucial for safety, performance, and longevity when wiring your home or office. Electrical cables are the backbone of any electrical installation, carrying power and data while ensuring your system runs smoothly and safely. With various options available on the market, choosing the right type for your needs can be overwhelming. This guide will walk you through some of the best electrical cables.

Types of Electrical Cables

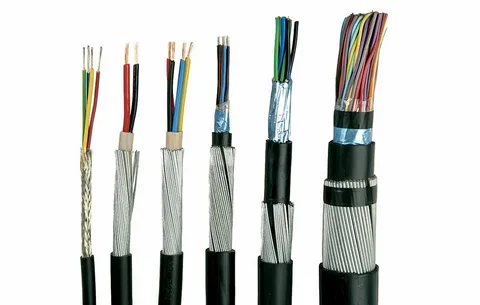

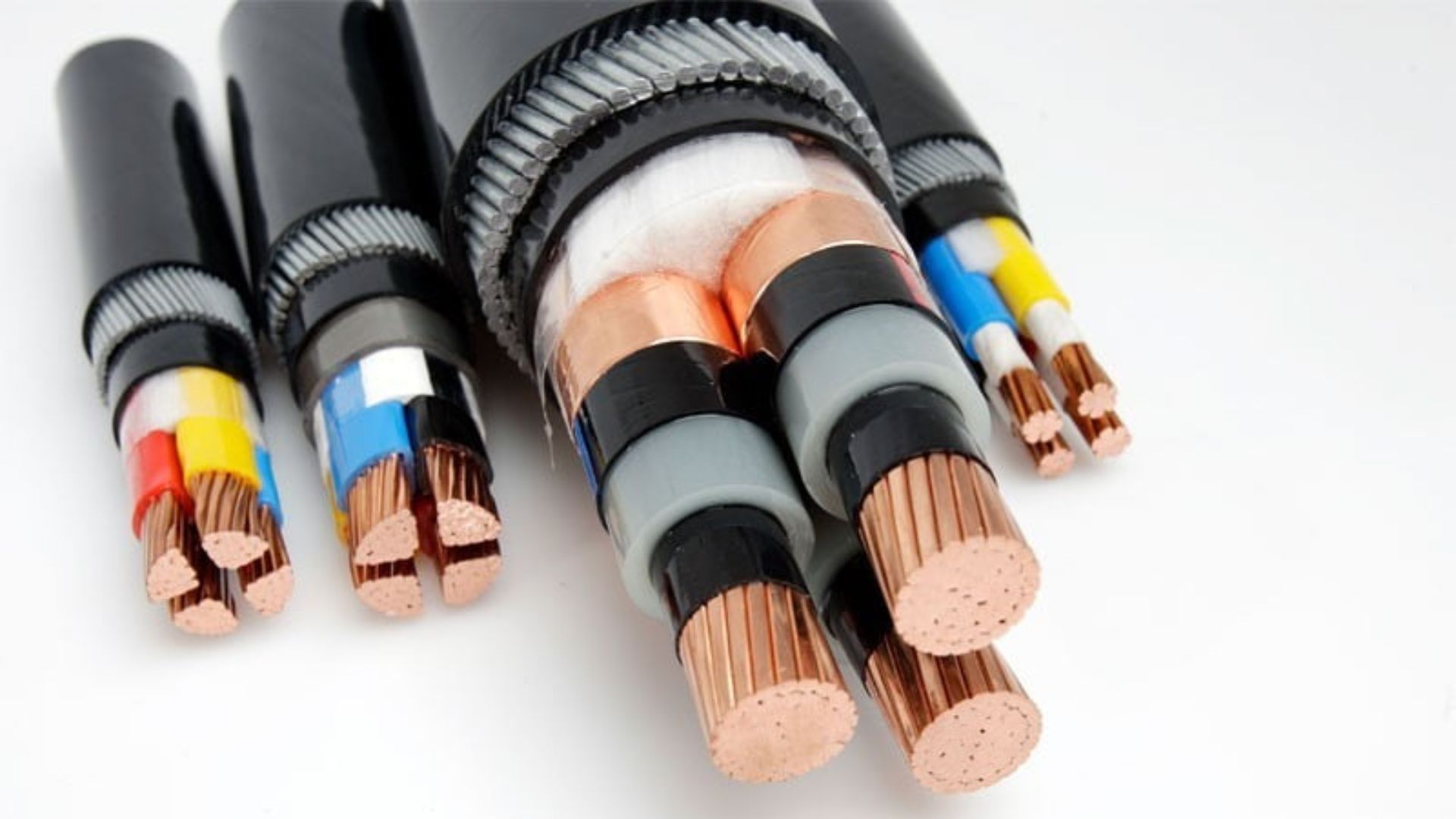

1. Armoured Cable

Armoured cables are designed to offer extra protection, especially in environments where the cable is likely to encounter physical damage. They feature one or more layers of metal (typically steel) armouring that shields the internal conductors. This construction makes them ideal for high-risk environments like construction sites, outdoor installations, and underground applications.

- Key Benefits:

- Provides resistance against mechanical damage

- Suitable for outdoor and underground use

- Often fire-resistant for added safety

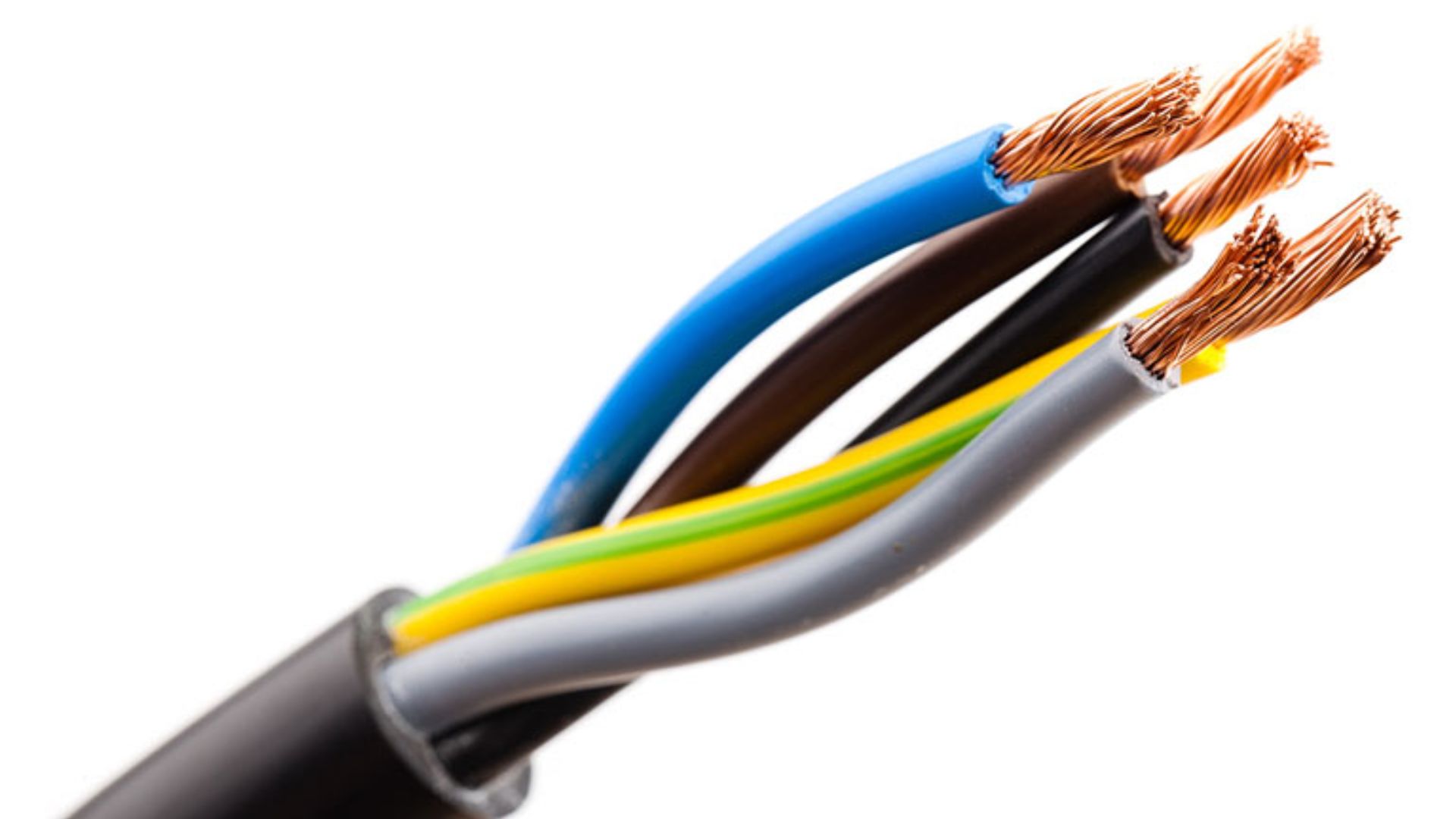

2. PVC Flexible Cable

PVC flexible cables are made with polyvinyl chloride insulation, offering great flexibility and resistance to environmental factors like moisture, heat, and abrasion. They are commonly used in applications where the cable needs to move or bend frequently without breaking or fraying.

- Key Benefits:

- Highly flexible, perfect for appliances and portable equipment

- Cost-effective and easy to install

- Resistant to chemicals and abrasion

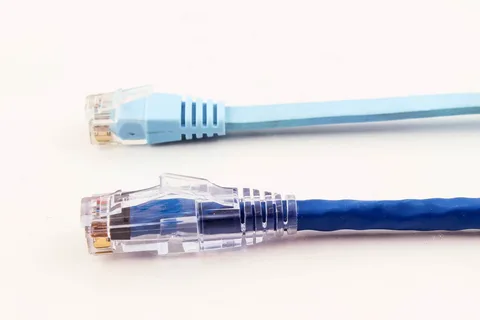

3. CAT 6 Cable

CAT 6 cables are a high-performance networking cable ideal for handling high-speed internet and data transfer. They support frequencies of up to 250 MHz and speeds of up to 10 Gbps, making them the go-to choice for modern home and office networks that require fast and reliable connections.

- Key Benefits:

- Offers higher data transfer rates and bandwidth compared to older cables

- Minimizes interference and crosstalk

- Perfect for high-speed internet and networked devices

4. Marine Cable

Marine cables are designed for use in harsh marine environments, including boats, ships, and offshore platforms. These cables are built to withstand saltwater, moisture, and extreme temperatures. They feature corrosion-resistant materials and waterproof insulation to maintain functionality even in the toughest conditions.

- Key Benefits:

- Corrosion-resistant and waterproof

- Designed to handle extreme environmental conditions

- Ensures reliable power and data transmission on ships and boats

5. Multicore Shielded Cables

Multicore shielded cables contain multiple conductors inside a single sheath, with added shielding to protect the signals from electromagnetic interference (EMI). These cables are essential for applications that require clear, uninterrupted signals, such as audio equipment, industrial automation systems, and telecommunications.

- Key Benefits:

- Protects against interference for clear and reliable signal transmission

- Suitable for high-frequency applications

- Minimizes external disturbances and noise

In Conclusion

Selecting the right electrical cable for your home or business wiring needs is essential for safety, efficiency, and performance. Understanding the different types of cables and considering factors like material, voltage, and environment will help you make an informed decision.

For top-quality electrical cables that meet the highest standards of performance and safety, Al Arz Electrical offers a wide selection of cables perfect for every application. Explore their product range today and ensure that your electrical systems are built on solid, reliable foundations.

Visit Al Arz Electrical now to find the perfect cable for your wiring project and experience unparalleled quality and service!