Introduction:

In the dynamic landscape of electrical engineering and infrastructure development, understanding electrical switchgear is crucial for buyers in the United Arab Emirates (UAE). Electrical switchgear serves as a vital component in managing and controlling electrical power distribution systems. This comprehensive guide aims to decode electrical switchgear, providing UAE buyers with valuable insights into its types, functions, applications, and considerations when selecting an Electrical Switchgear Supplier in UAE.

Understanding Electrical Switchgear:

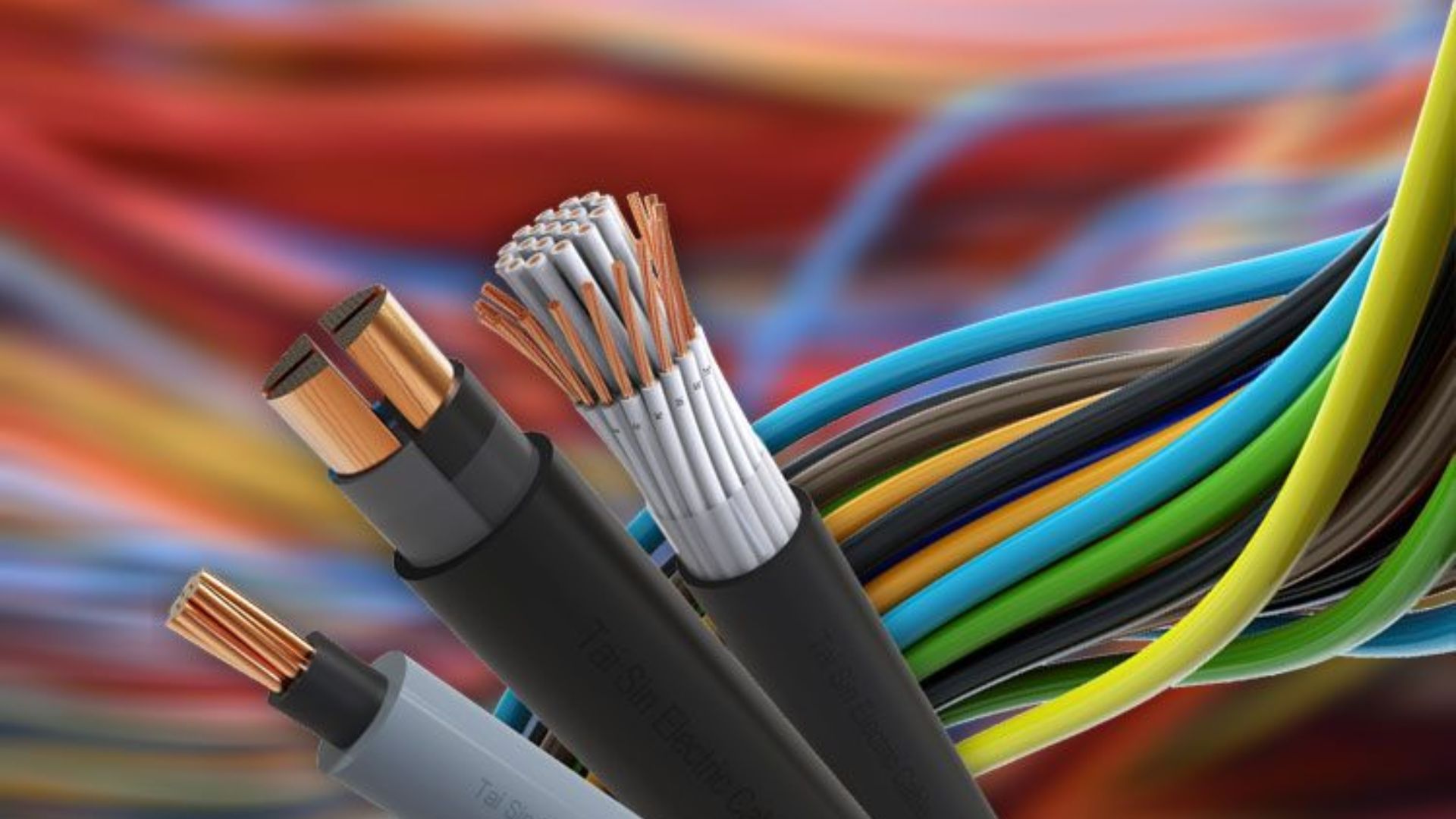

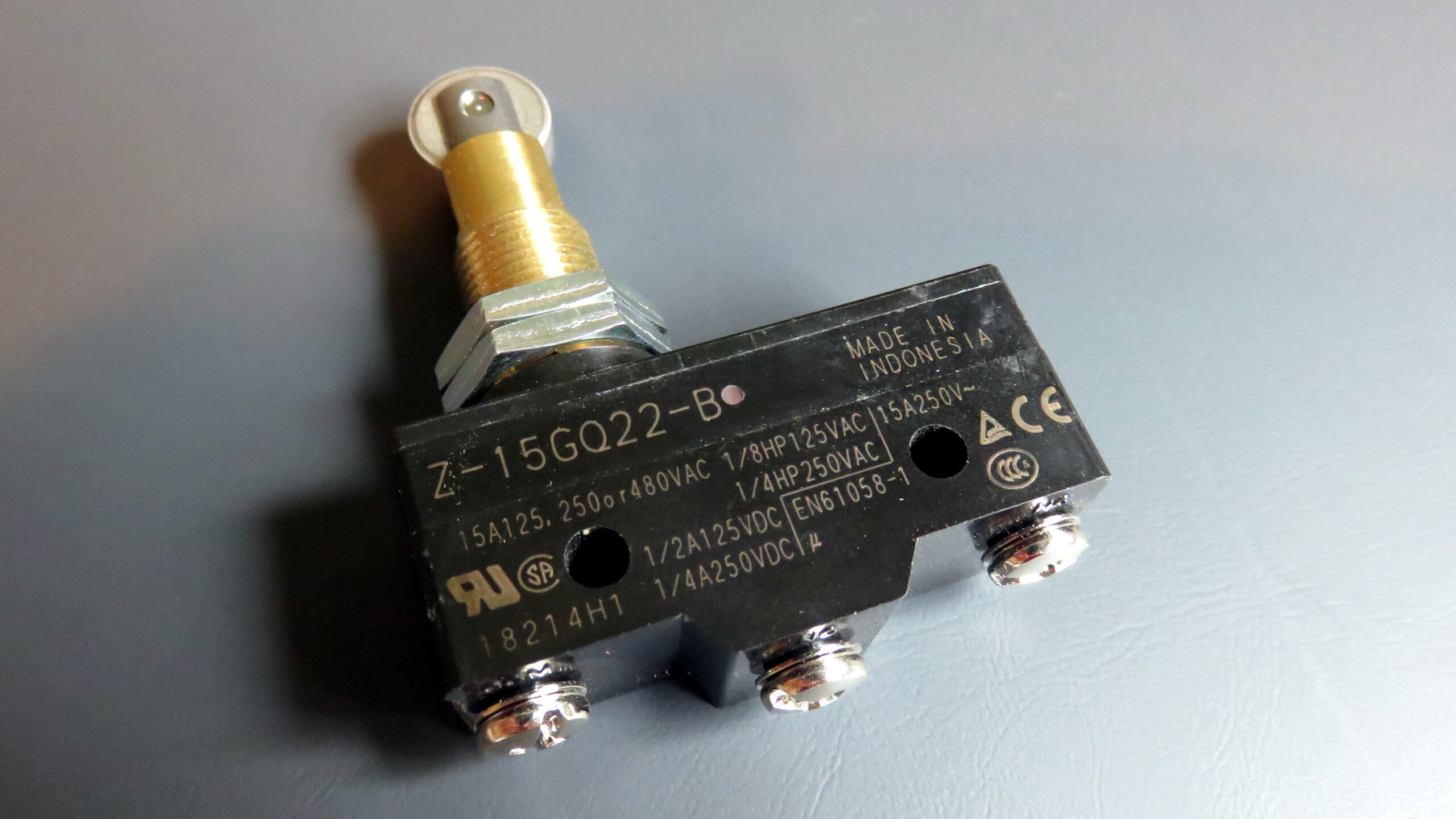

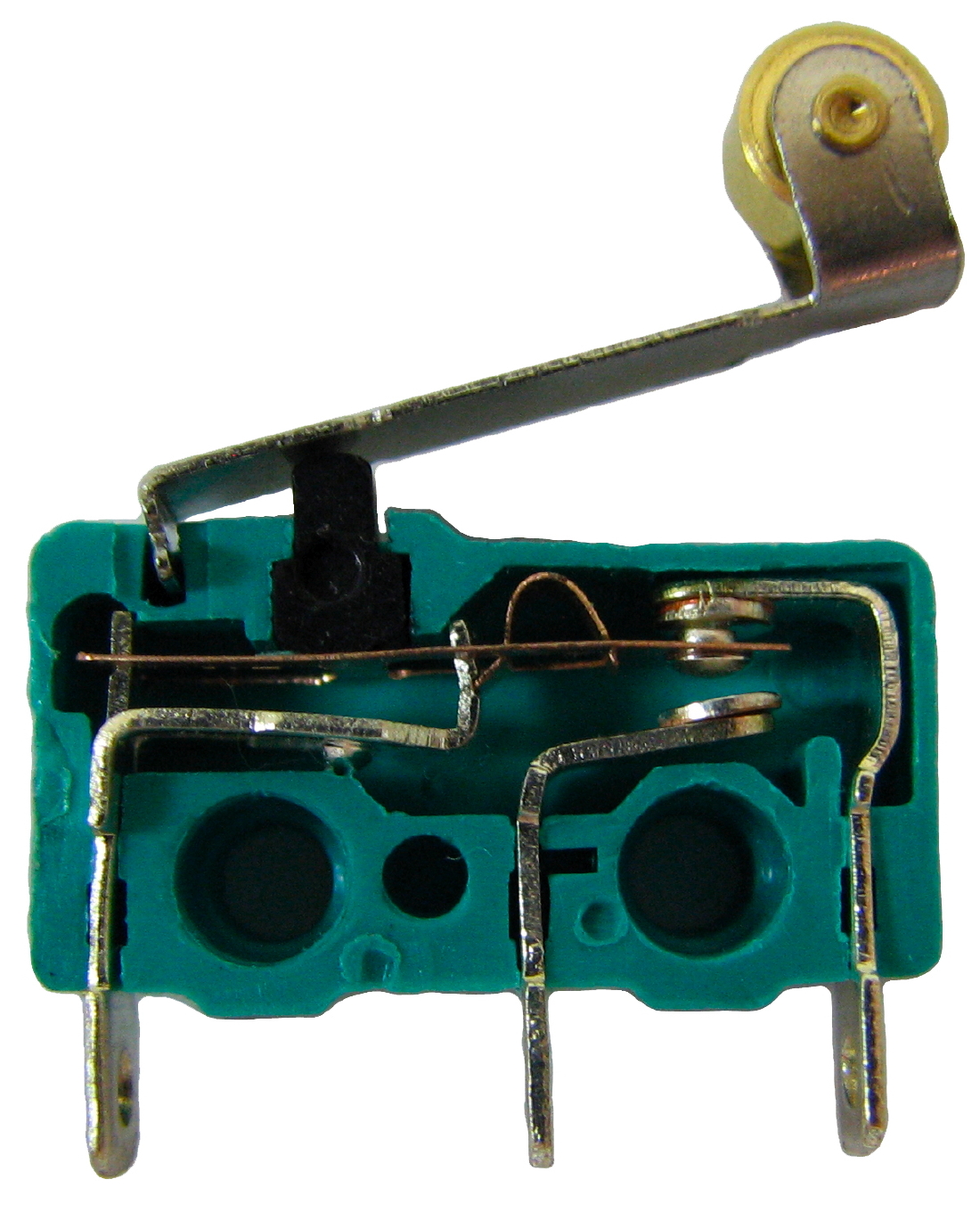

Electrical switchgear is a crucial apparatus used to control, protect, and isolate electrical circuits and equipment in power distribution systems. It comprises various components, including circuit breakers, fuses, disconnect switches, relays, and control panels, which work together to ensure the safe and efficient operation of electrical networks. Switchgear plays a pivotal role in safeguarding electrical systems against overloads, short circuits, and other faults, thereby enhancing reliability and safety.

Types of Electrical Switchgear:

Low-Voltage Switchgear:

Low-voltage switchgear is commonly used in residential, commercial, and light industrial applications. It operates at voltages below 1 kV and includes components such as circuit breakers, contactors, and distribution panels. Low-voltage switchgear is essential for controlling power distribution and protecting electrical equipment from damage caused by overloads and short circuits.

Medium-Voltage Switchgear:

Medium-voltage switchgear is utilized in medium-sized industrial facilities, commercial buildings, and utility substations. It operates at voltages ranging from 1 kV to 36 kV and incorporates advanced protection and control mechanisms. Medium-voltage switchgear is critical for managing power distribution and minimizing downtime in critical infrastructure.

High-Voltage Switchgear:

High-voltage switchgear is designed for applications requiring voltages exceeding 36 kV, such as large industrial plants, power generation facilities, and utility substations. It comprises robust circuit breakers, disconnect switches, and protective relays capable of withstanding high currents and voltages. High-voltage switchgear ensures grid stability, fault isolation, and system protection in high-power environments.

Selecting an Electrical Switchgear Supplier in UAE:

When choosing an electrical switchgear supplier in UAE, several factors should be considered:

- Reputation and Experience: Select a supplier with a solid reputation and extensive experience in providing high-quality switchgear solutions.

- Product Range: Look for a supplier that offers a diverse range of switchgear products to meet your specific requirements and applications.

- Quality and Compliance: Ensure that the supplier adheres to international quality standards and regulatory requirements to guarantee the reliability and safety of switchgear products.

- Technical Support and After-Sales Service: Choose a supplier that provides comprehensive technical support, installation assistance, and after-sales service to ensure the seamless integration and operation of switchgear systems.

Conclusion:

Electrical switchgear plays a critical role in the safe and efficient operation of electrical systems in the UAE. By understanding the types, functions, and considerations for selecting an electrical switchgear supplier in UAE, buyers can make informed decisions that meet their infrastructure needs and requirements. As infrastructure development continues to evolve, the partnership between buyers and electrical switchgear suppliers remains essential in driving innovation, reliability, and sustainability in electrical networks.