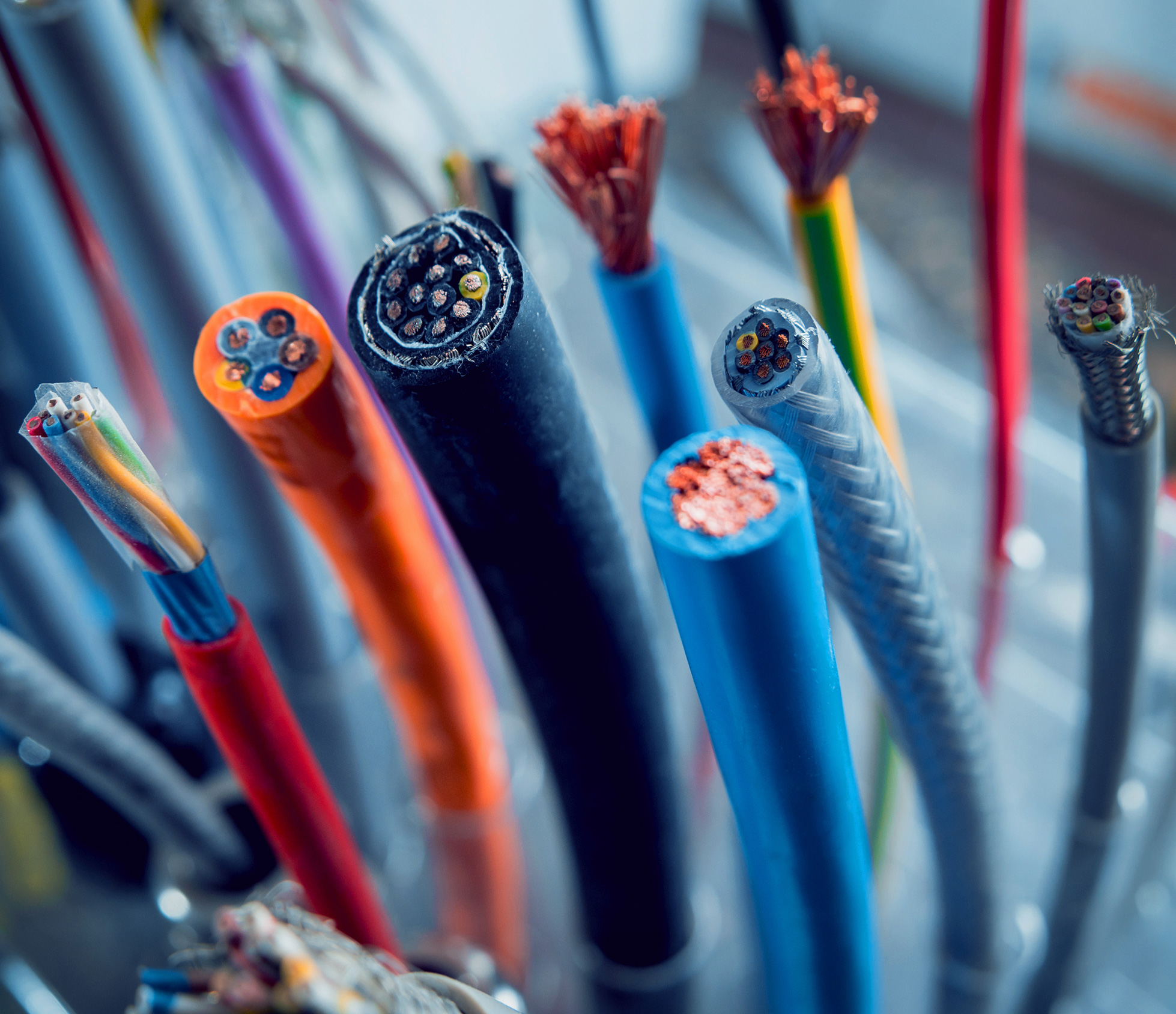

When it comes to electrical installations, selecting the right cables and wires is crucial for ensuring safe and efficient operations. With a plethora of options available in the market, it can be overwhelming to choose the most suitable cables and wires for your specific needs. This blog aims to highlight the key factors that should be considered when making this important decision.

Conductivity and Current Capacity

The conductivity of cables and wires is a vital factor to consider. Higher conductivity allows for better transmission of electrical current, minimizing energy loss and ensuring optimal performance. Additionally, it is important to assess the current capacity of the cables and wires to ensure they can handle the anticipated load without overheating or causing damage to the electrical system.

Insulation Material and Temperature Rating

The insulation material of cables and wires plays a crucial role in maintaining electrical safety. Different environments require specific types of insulation materials to withstand temperature variations, moisture, chemicals, and other potential hazards. It is essential to choose cables and wires with insulation materials that are suitable for the intended application. Additionally, considering the temperature rating of the lines and wires ensures they can operate safely within the specified temperature range.

Power Rating

The ability of cables and wires to handle the necessary voltage levels without electrical breakdown or failure depends on their voltage rating. To guarantee safe and dependable operation, it is crucial to select cables and wires with a voltage rating higher than the electrical system’s maximum voltage.

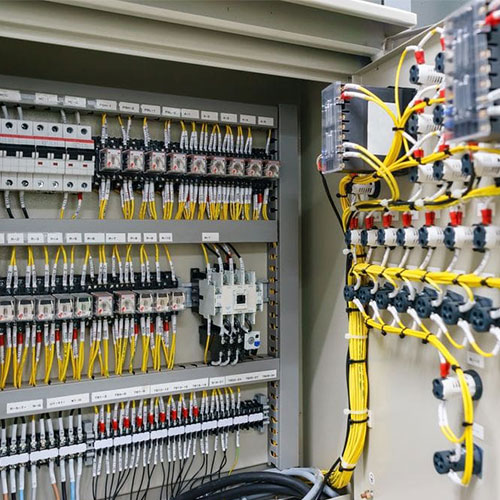

Flexibility and Robustness

Particularly when cables and wires need to be installed in places where frequent movement or bending is anticipated, flexibility and durability are crucial factors to take into account. Flexible cables and wires make installation simpler and less likely to result in breakage or damage. Additionally, choosing cables and wires with tough coatings and construction lengthens their useful lives and lowers the frequency of replacement and maintenance.

Environmental Conditions

Different environments present varying challenges for cables and wires. Factors such as exposure to moisture, sunlight, extreme temperatures, chemicals, and mechanical stress should be considered. Choosing cables and wires that are specifically designed to withstand these environmental conditions ensures long-lasting performance and prevents potential hazards.

Compliance with Standards and Regulations

Ensure that the cables and wires you choose comply with relevant industry standards and regulations. This ensures that they have undergone rigorous testing and meet the required safety and performance standards. Compliance with standards also assures quality and reliability.

Cost and Budget

While cost should not be the sole determining factor, it is important to consider the budgetary constraints when selecting cables and wires. Balancing the desired quality and performance requirements with the available budget is essential. Investing in high-quality cables and wires may initially incur a higher cost but can save money in the long run by reducing maintenance and replacement expenses.

Conclusion

Choosing the right electrical cables and wires is a critical decision that can significantly impact electrical installations’ safety, performance, and longevity. Considering factors such as conductivity, insulation material, voltage rating, flexibility, durability, environmental conditions, compliance with standards, and budgetary constraints ensures the selection of cables and wires that meet the specific requirements of the electrical system. By carefully evaluating these key factors, you can make informed decisions that contribute to the smooth and reliable functioning of your electrical installations.