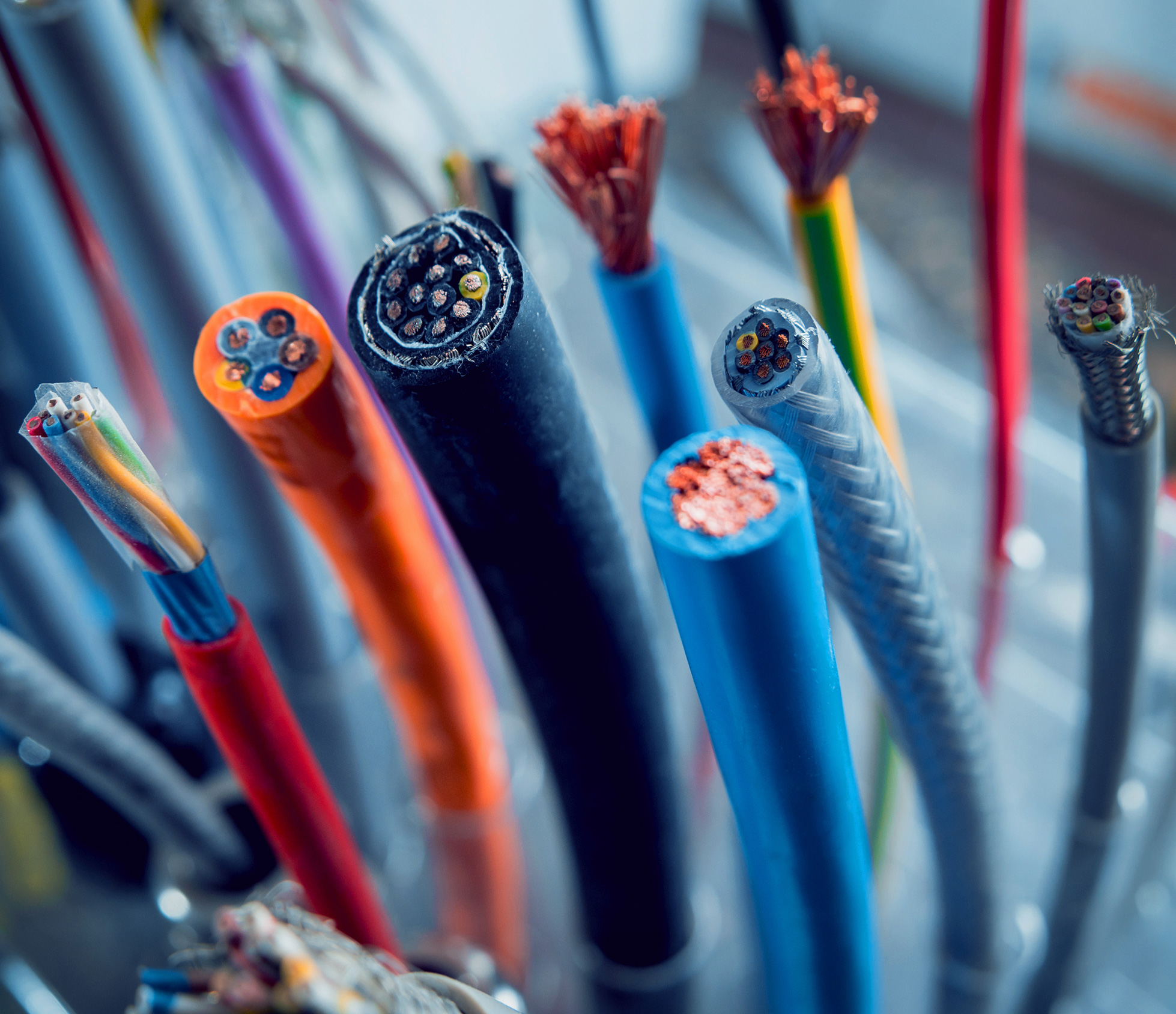

In the electrical industry, aspect such as quality of cables can affect the performance of systems and the safety of the users. Electrical cables are employed in different functions in exercises as simple as lighting up a home to complicated industrial uses. Producers of electrical cables ensure that their cables conform to various situations in the various environments in terms of quality and safety. This blog focuses on the main measures that electrical cable supplier takes to guarantee that they supply products that are safe to use.

Electrical cables are the power distribution networks, and any sop in their quality can be very disastrous leading to equipment damage, power blackouts or fire explosions. Due to these risks, there is high standards that have to be followed by suppliers in the electrical cable market with an aim of ensuring that the highest performance and safety is achieved. While the manufacturers are involved in the production of well compliant cables, the suppliers are also involved in the confirmation and sustenance of the standards. Suppliers of electrical cables guarantee the products they deliver to the market to meet the standard specifications of that industry while at the same time surpassing the customers’ demands.

Quality Assurance Processes

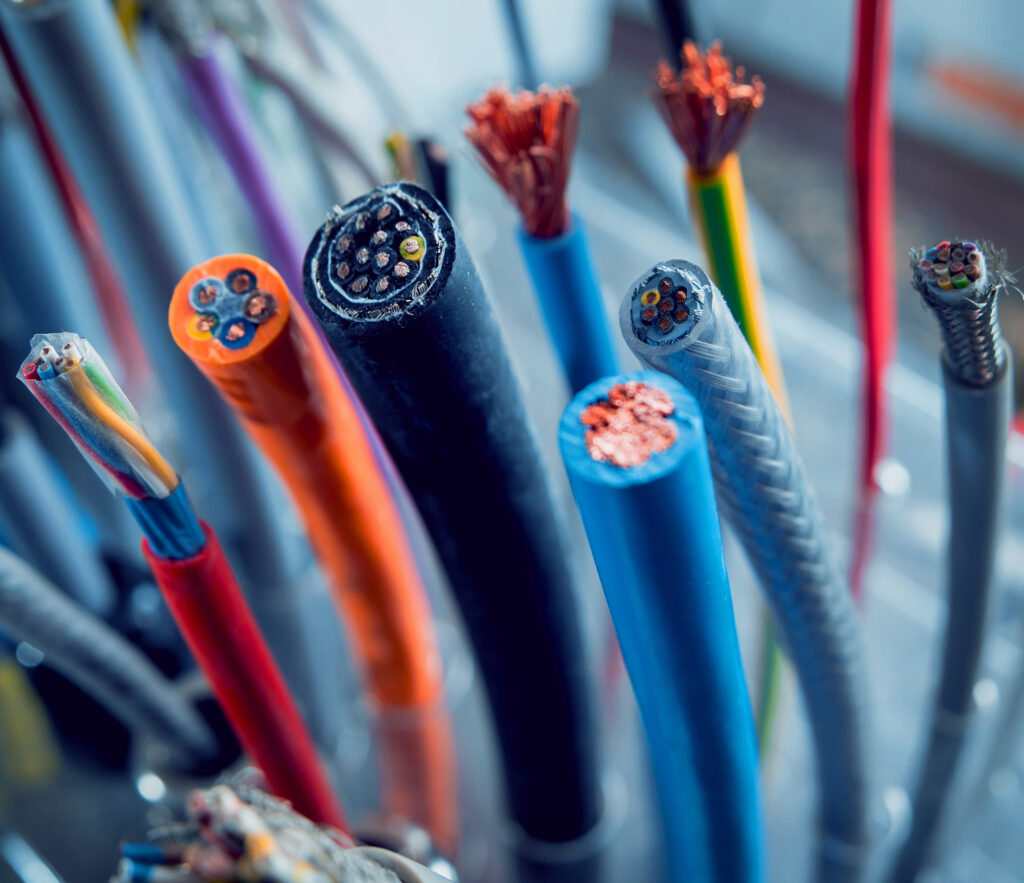

Quality assurance measures are applied to ensure the cables meet the set requirements. This usually involves the initial buying of the cables from recognized OEM suppliers who manufacture their cables within specific globally recognized electrical codes and standards such as the IEC or UL. Such certifications ensure that the manufactured products are safe for the customer and also reliable to execute the desired function.

On obtaining cables, suppliers subsequently carry out their quality assessments. This includes, but is not limited to, simple tests by observation that show gross areas that could have been affected, such as the separator or the insulation layer of the cable or the conductor material. Electrical resistance and tensile strength tests also ensure that the cables can cope with different environments and usage situations.

Compliance with Safety Standards

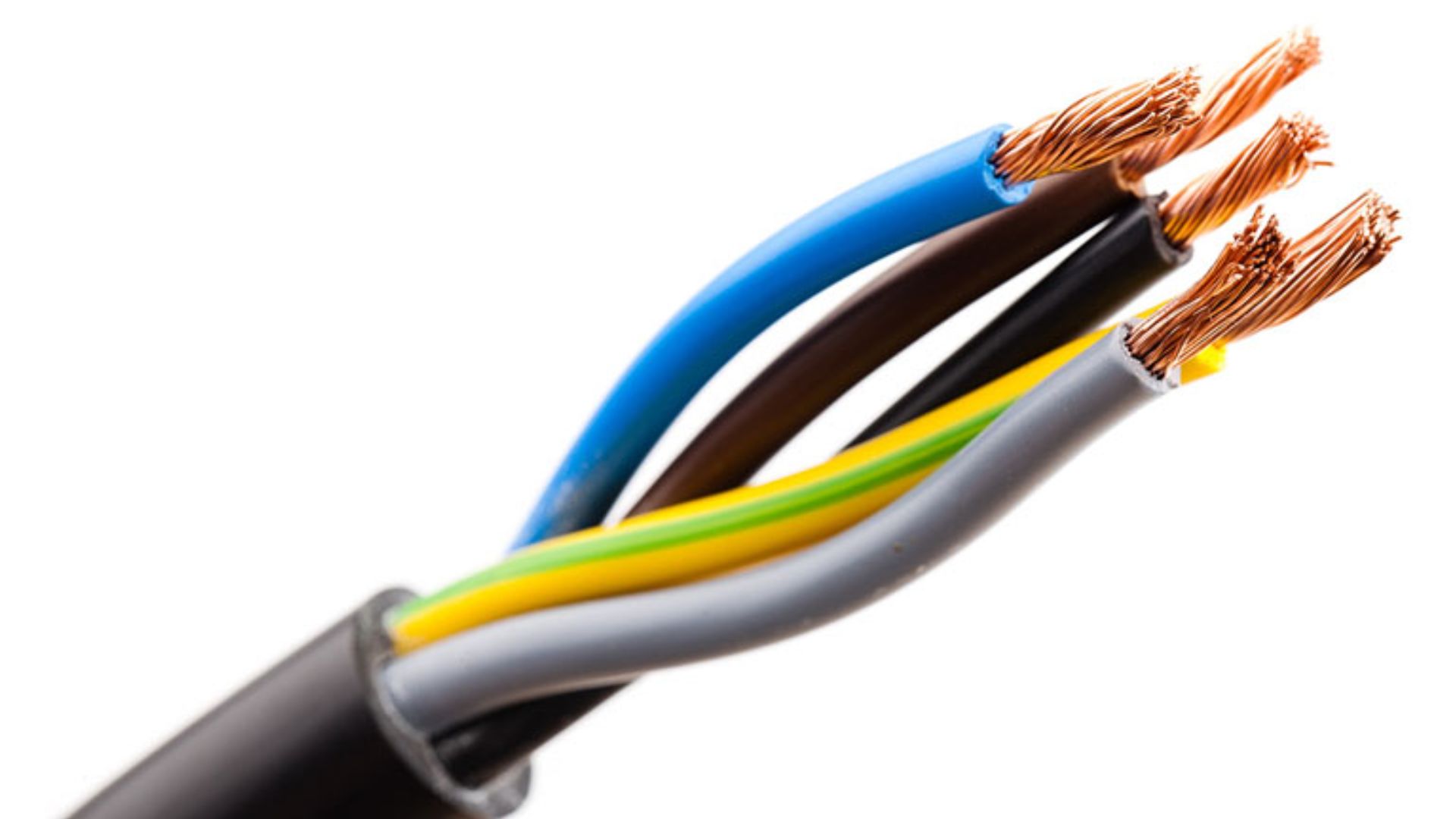

It is extremely important that electrical cable distribution maintains safety measures that correspond with international regulates and standards. It is common for suppliers, therefore, to operate subject to legislation and requirements for their products so that they can be safe for use. These include the requirement to conform with local electrical codes as well as the international voltage, insulation and fire resistances standards.

Some suppliers engage the testing laboratories to conduct tests and provide necessary certifications of cables. These certifications ensure that the products attain characteristics such as being fire resistant, water proof and immune to high heat depending on the application. Adherence to these safety standards makes it possible to use the cables for either residential, commercial or industrial purposes and at the same time meet the necessary safety requirements.

Continuous Monitoring and Traceability

However, not only after the first tests; suppliers of electrical cable also constantly monitor their products. They employ tracking system with information to give a way to a specific batch of cables so that they can be recalled and tested on compliance. Such traceability guarantee that if in the future there are some complications affecting the said products, they can easily be traced and repaired.

However, suppliers do send various documents and papers like conforming certificates and technical sheets to the customers and explain to them about the quality and safety of the cables bought from them. These documents explain the parameters of the cable such as the voltage rating of the cables and the type of insulation used as well as the test results and the disclosure help to build the customer base.

Conclusion

The suppliers of electrical cables have key responsibility in delivering quality and safe cable products. They ensure adherence to quality standards, safety edicts of electronics relevant to the global market as well as offering regular checks to ensure that they meet the needs of complex electric systems. Thus, Electrical cable suppliers ensure their customers and at the same time improve on the aspects needed for electrical safety and performance.