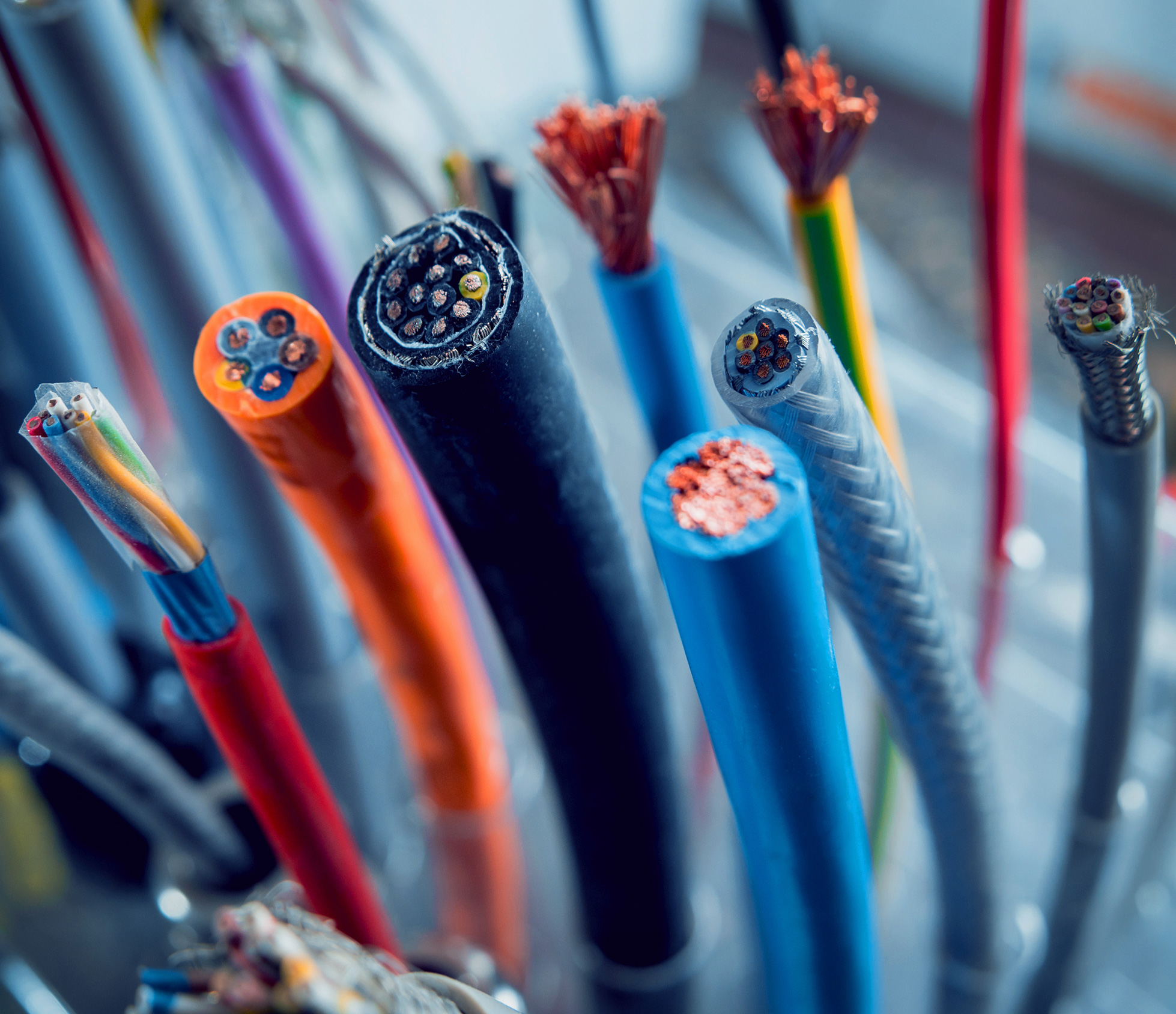

Wires, both solid and stranded, are commonly used in electrical equipment such as cable assemblies and wire harnesses. Solid wires have a solid core, whereas stranded wires are made up of multiple thinner wires twisted together to form a bundle. Each offers various advantages, with the best option for a given application depending on the project’s specifics. Amperage load, Use case, Prices, Metal kind, Wire gauge, and, most significantly, selecting a dependable Electrical Cable Supplier such as Al Arz Electrical in UAE are some of the elements that may affect the choice between stranded vs. solid wire.

Understanding the distinctions between the two kinds of wires might assist you in selecting the best solution for your needs. The following details should aid in the choosing process.

What does stranded wire do?

These small, coiled wires are compressed and insulated using non-conductive materials. Since the stranded wire is more flexible, it may be bent and twisted to fit into intricate shapes and connect electrical components in small spaces. Stranded wire is less prone to split or sever because it is more malleable and softer than solid wire. Circuit boards, speaker lines, and electrical devices are widely utilized indoors with it.

What is Solid Wire?

Stranded wire is much lighter and thinner than solid metal core wire. It is ideal for outdoor applications that require increased durability and higher currents. This robust, low-cost wire is resistant to harsh weather, extreme weather conditions, and frequent transit. Large currents are commonly transported through infrastructural development, automobile management, and a range of different applications.

The main distinctions between solid and stranded wires

When contrasting stranded and solid wire, it is vital to consider the benefits and drawbacks of the two distinctly different types of wire. Based on how various wire qualities relate to their intended use and project requirements, a comparison reduces the available possibilities. The requirements for flexibility, weather resistance, and resistance to splitting or severing must first be ascertained for your application. Choose the wire that best meets those specifications next.

Important differences between stranded and solid copper wire include the following:

- stranded wire’s lower current capacity compared to solid wire

The solid cable has less surface area for dissipation because of its thickness. More dissipation occurs because thinner wires in the stranded wire have a greater surface area and air gaps than individual strands. In in-house wiring, solid wire outperforms stranded wire in terms of current capacity.

- Routing

Stranded wires are easier to bend and bend around objects than solid wires because they are more adjustable and pliable.

- Flexibility

Stranded wires are often more stretchy than solid wires, allowing them to take more vibrations and stretch without breaking. Solid wires may need to be replaced more frequently than stranded wires in circumstances where there is a lot of movement or vibration.

- Cost

Solid wire has lower production costs than stranded wire, making it the most cost-effective option.

- Manufacturing simplicity

Because solid wire has a single core, it is significantly easier to produce. Stranded wires need more sophisticated production techniques to connect the thinner wires.

- Distance

Solid wires are a superior alternative for longer distances since they dissipate less current. Stranded wire works effectively over short distances.

- Superiority

When it refers to stranded versus solid wire, there is no clear winner. Each strategy has distinct advantages in certain situations.

Al Arz Electrical Wire & Cable Wire Solutions

For many years, Al Arz Electrical has been a leading Electrical Socket Suppliers and a well-known manufacturer of high-quality standard and bespoke electronic wire, molded cable assemblies, wiring harnesses, cable, and power supply cables.

When you work with the top Electrical Products Suppliers in UAE, you will have access to our whole team’s knowledge to ensure the success of your project. Contact us or submit a quote request immediately for more information on our capabilities and product ranges.